Showroom

Pneumatic feeders are widely used in stamping and pressing applications, delivering accurate sheet feeding with minimal maintenance. Operated through compressed air, they ensure smooth and reliable performance in high-speed production lines. Their compact design, cost-effectiveness, and versatility make them suitable for diverse metalworking and industrial operations.

Motorized decoilers are designed to hold and unwind coils with consistent speed and efficiency. Equipped with electric drives, they ensure smooth coil handling while reducing material wastage. These machines are suitable for heavy-duty applications, supporting continuous production in stamping, cutting, and forming industries with enhanced safety and stability.

NC servo feeders provide precise and programmable feeding solutions for metal stamping and punching lines. Controlled by advanced servo motors, they allow flexible length adjustments, ensuring accuracy and high productivity. These feeders are widely used in industries requiring efficiency, automation, and consistent quality in sheet processing applications.

Motorized straighteners are essential for removing coil set and irregularities from sheet materials before processing. Designed with powered rollers, they deliver uniform straightening results, ensuring smooth feeding into presses and cutting machines. These systems improve product quality, reduce downtime, and enhance efficiency in coil handling operations.

Decoiler cum straighteners combine two operationscoil unwinding and sheet straighteninginto one compact system. They save space, reduce handling time, and improve efficiency in production lines. Designed for continuous sheet processing, these machines provide uniform material feeding, making them ideal for stamping, punching, and roll-forming industries.

Horizontal decoilers are designed to handle delicate and narrow coils efficiently. They provide smooth unwinding without damaging the material edges, making them suitable for sensitive sheet processing. With stable construction and easy coil loading, these systems are widely used in wire, strip, and light metal coil applications.

Spray lubricating systems ensure precise application of lubricants onto metal sheets or coils during stamping and forming. They reduce friction, extend tool life, and improve product finish. These systems offer controlled spray patterns and adjustable flow, making them highly efficient and cost-effective for automated production processes.

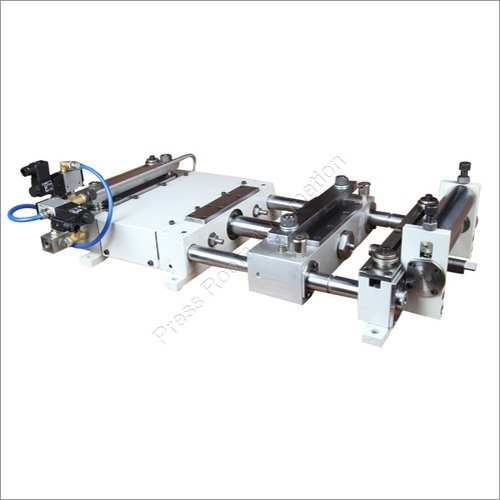

Mechanical roll feeders deliver sheet material with accuracy and reliability in stamping presses. Driven directly by press mechanisms, they ensure synchronized feeding with minimal power consumption. These feeders are durable, low-maintenance, and suitable for high-speed operations, making them a cost-effective solution for long-term metalworking applications.

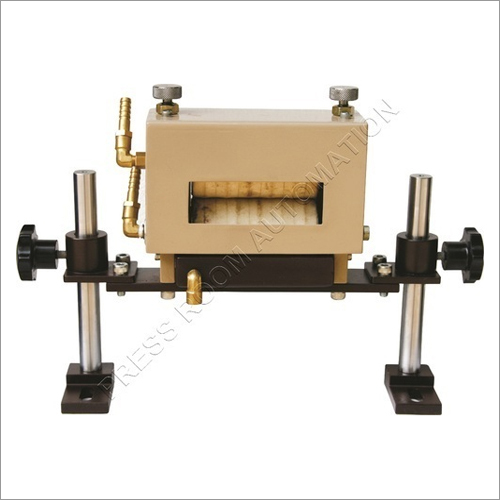

Roller lubricating systems provide consistent coating of lubricants onto sheet materials using specially designed rollers. They help reduce wear, enhance forming quality, and prevent surface defects. Widely used in stamping and pressing operations, these systems deliver uniform lubrication while minimizing wastage and improving overall tool life and efficiency.

Cut to length lines are designed for cutting metal coils into sheets of precise dimensions. Equipped with straightening, feeding, and shearing units, they ensure accuracy and efficiency. These lines are widely used in automotive, appliance, and construction industries, delivering consistent sheet quality with reduced material wastage.

Zig zag servo feeders optimize coil material usage by enabling zig zag feeding patterns in stamping operations. This reduces scrap, increases efficiency, and enhances cost savings. Controlled by servo motors, these feeders offer flexibility, accuracy, and productivity, making them ideal for high-speed and precision-driven production environments.

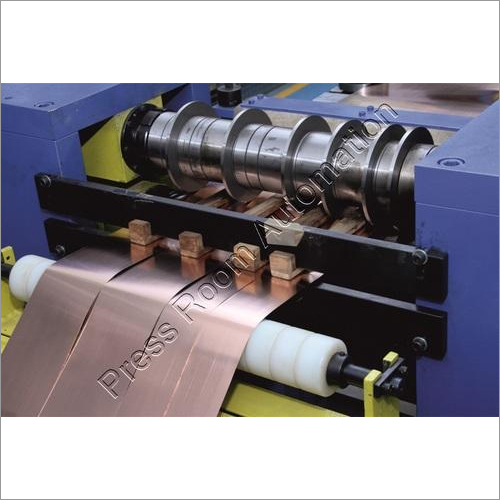

Slitting lines are designed to cut wide metal coils into multiple narrower strips with high precision. Equipped with sharp rotary knives, they ensure smooth edges and uniform strip widths. These lines are essential in steel, aluminum, and non-ferrous industries for efficient coil processing and material optimization.

Wire straighteners are used to remove bends and coil set from wires before further processing. Designed with multiple rollers, they deliver uniform straightening results for different wire diameters. These machines are widely applied in industries such as welding, spring making, and wire forming for consistent quality output.

NC leveller feeders combine feeding and leveling functions in a single system. Equipped with servo controls, they provide high precision and programmable feeding lengths. These feeders ensure flat and defect-free sheets, making them suitable for high-performance stamping and punching applications where accuracy and productivity are critical.

Component levellers are designed to flatten stamped or formed parts, ensuring smooth and uniform surfaces. They remove residual stresses and distortions from components, enhancing quality and assembly fit. Widely used in automotive and appliance industries, these machines improve the dimensional accuracy and reliability of manufactured parts.

Mechanical gripper feeders provide accurate feeding of sheets and strips using mechanical grippers synchronized with press operations. Known for durability and reliability, they are ideal for high-speed stamping applications. These feeders offer low maintenance and ensure smooth feeding, making them a cost-effective solution for long production runs.

Conveyor parts include belts, rollers, chains, and components essential for smooth conveying operations. Designed for durability and efficiency, they ensure minimal downtime and consistent material flow in production lines. These parts are widely used in manufacturing, packaging, and assembly industries to enhance productivity and operational reliability.

S-loop with precision straighteners are advanced coil processing systems that ensure optimal sheet flatness and consistent feeding. By incorporating an S-loop, material tension is balanced, allowing better straightening results. These systems are widely used in automotive, electrical, and stamping industries where high precision is required.

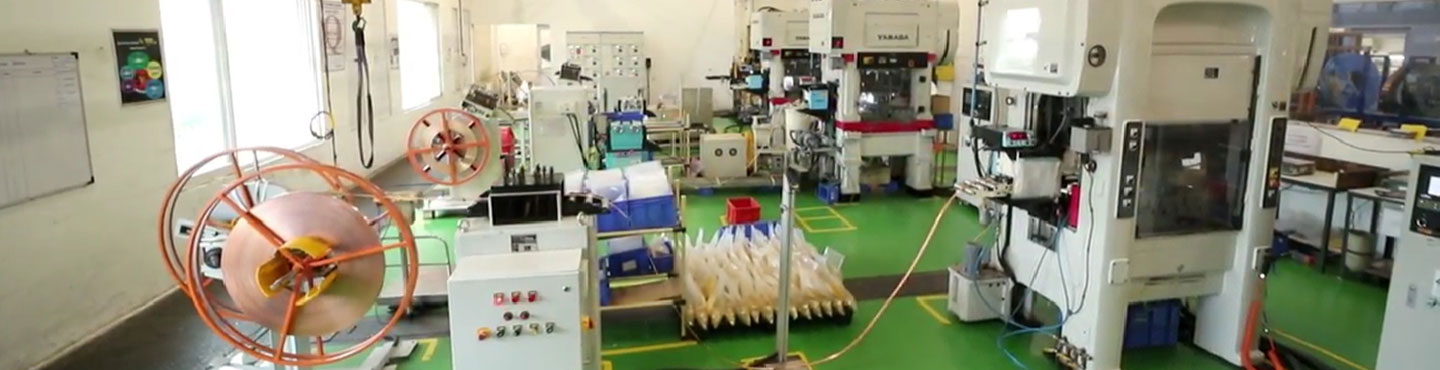

Coil feeding lines integrate decoiling, straightening, and feeding processes for efficient sheet handling. Designed to minimize material waste and increase productivity, they ensure accurate feeding into presses or cutters. These lines are widely used in automotive, appliance, and electrical industries for high-volume and precision-driven production operations.