Pneumatic Feeder with Motorized Decoiler 500 Kgs.

100000 INR/Unit

Product Details:

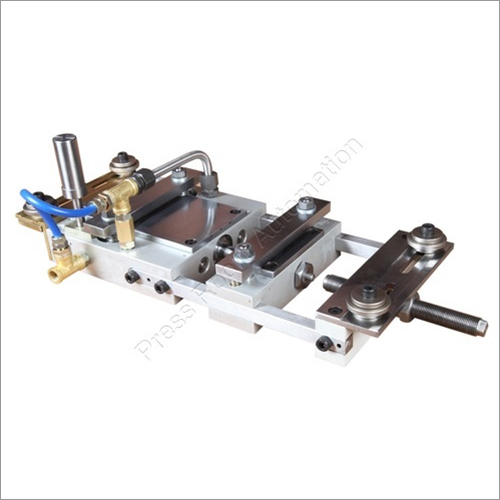

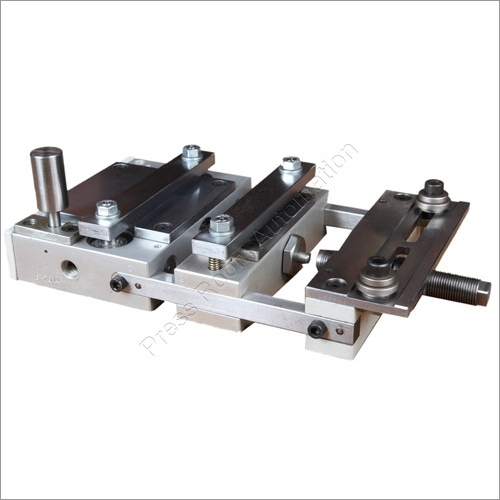

- Media Pneumatic and motorized system

- Structure Robust and durable structure with ergonomic design

- Material Steel designed to handle weights up to 500 Kgs

- Air Consumption Low air consumption suitable for pneumatic operations

- Click to view more

X

Pneumatic Feeder with Motorized Decoiler 500 Kgs. Price And Quantity

- 100000 INR/Unit

- 100000.00 - 500000.00 INR/Unit

- 1 Unit

- Includes overload protection and safety guards

- Hardened alloy steel rollers for wear resistance

- Suitable for stamping, forming, and progressive die operations

- Operator-friendly interface with emergency stop

- Base plate with vibration pads for stable operation

- Operates efficiently at standard shop compressed air (5-7 bar)

- Powder-coated industrial finish for corrosion protection

- Adjustable as per strip requirement

- Up to 500 Kgs

- Programmable stroke length for feeding materials

- Motorized automatic decoiler integrated with pneumatic feeder

Pneumatic Feeder with Motorized Decoiler 500 Kgs. Product Specifications

- Robust and durable structure with ergonomic design

- Low air consumption suitable for pneumatic operations

- Pneumatic and motorized system

- Steel designed to handle weights up to 500 Kgs

- Includes overload protection and safety guards

- Hardened alloy steel rollers for wear resistance

- Suitable for stamping, forming, and progressive die operations

- Operator-friendly interface with emergency stop

- Base plate with vibration pads for stable operation

- Operates efficiently at standard shop compressed air (5-7 bar)

- Powder-coated industrial finish for corrosion protection

- Adjustable as per strip requirement

- Up to 500 Kgs

- Programmable stroke length for feeding materials

- Motorized automatic decoiler integrated with pneumatic feeder

Product Description

Try Now the Pneumatic Feeder with Motorized Decoiler 500 Kgs a majestic solution blending competitive pricing with inestimable industrial value. Featured by its robust structure, operator-friendly control panel and ergonomic design, it reliably handles coil weights up to 500 Kgs. The motorized automatic decoiler, together with adjustable feed width and programmable stroke length, ensures valuable precision in stamping, progressive die, and forming operations. Hardened alloy steel rollers provide wear resistance, while base vibration pads guarantee stability. Supplier and manufacturer certified across India, this feeder offers a powder-coated finish for superior corrosion protection.

Usage & Features of Pneumatic Feeder with Motorized Decoiler

Used for stamping, forming, and progressive die operations, this versatile feeder offers an adjustable feed width for different strip requirements. Its motorized automatic decoiler enables seamless material handling, while programmable stroke length allows precise feeding. Hardened alloy steel rollers promise longevity and minimal wear, complemented by low air consumption and overload protection. The feeders ergonomic and robust design supports both ease of use and stability in high-performing industrial settings.

Payment, Delivery & Certifications

Quotation can be requested for competitive pricing on this valuable feeder. Upon acceptance, a swift handover and exchange process follows, ensuring timely delivery across India. Standard certifications validate safety, quality, and operational reliability, meeting industry benchmarks. Payment terms are flexible, tailored to project requirements, and include transparent invoicing. Efficient logistics guarantee delivery timeframes are adhered to, while the feeder is handed over with all relevant documentation and usage certifications.

Usage & Features of Pneumatic Feeder with Motorized Decoiler

Used for stamping, forming, and progressive die operations, this versatile feeder offers an adjustable feed width for different strip requirements. Its motorized automatic decoiler enables seamless material handling, while programmable stroke length allows precise feeding. Hardened alloy steel rollers promise longevity and minimal wear, complemented by low air consumption and overload protection. The feeders ergonomic and robust design supports both ease of use and stability in high-performing industrial settings.

Payment, Delivery & Certifications

Quotation can be requested for competitive pricing on this valuable feeder. Upon acceptance, a swift handover and exchange process follows, ensuring timely delivery across India. Standard certifications validate safety, quality, and operational reliability, meeting industry benchmarks. Payment terms are flexible, tailored to project requirements, and include transparent invoicing. Efficient logistics guarantee delivery timeframes are adhered to, while the feeder is handed over with all relevant documentation and usage certifications.

FAQs of Pneumatic Feeder with Motorized Decoiler 500 Kgs.:

Q: How does the motorized decoiler improve the feeding process?

A: The motorized decoiler automates coil handling, ensuring smooth and consistent material feed, minimizing manual intervention and optimizing efficiency during stamping and forming operations.Q: What is the benefit of hardened alloy steel rollers in this feeder?

A: Hardened alloy steel rollers provide exceptional wear resistance, ensuring durable performance and reducing maintenance, especially during continuous industrial usage.Q: When can I expect delivery after placing an order?

A: Typically, delivery is initiated soon after confirmation and exchange of necessary documents or quotation acceptance, with timelines specified during the handover process.Q: Where is the Pneumatic Feeder with Motorized Decoiler manufactured and supplied?

A: This feeder is manufactured and supplied in India, with nationwide logistics and support for industrial clients.Q: What safety features are integrated into the feeder?

A: The feeder includes overload protection, safety guards, and an emergency stop on the operator-friendly control panel for enhanced operational safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free