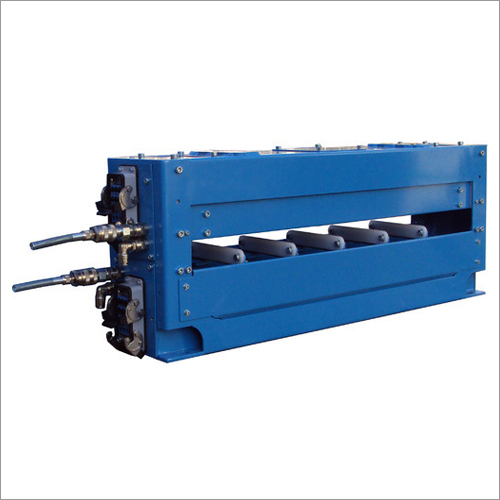

EPC 4 Or 8 Point Spray Lubrication System

Product Details:

- Model No EPC-4P / EPC-8P

- Automatic Grade Automatic

- Filter Type Fine Mesh Type

- Material Steel Body with ABS Cover

- Capacity 4 Or 8 Lubrication Points

- Usage & Applications Industrial Machinery Lubrication, CNC Machines, Textile Machinery, Packaging Equipment

- Size Standard / Custom Available

- Click to view more

EPC 4 Or 8 Point Spray Lubrication System Price And Quantity

- 2000000 INR

- 1 Unit

- Easy Plug & Play

- PLC / Manual Switch Compatible

- Electric Gear Pump

- Microprocessor Based Controller

- 4mm / 6mm

- IP54

- LED Indicator for Status & Error

- 3 Liters

- Overload & Dry Run Protection

- Wall / Panel Mount

- 0.05-0.2 ml (per point, adjustable)

- 2-7 bar adjustable

- 5°C to 55°C

EPC 4 Or 8 Point Spray Lubrication System Product Specifications

- 12 kg

- Industrial Machinery Lubrication, CNC Machines, Textile Machinery, Packaging Equipment

- Standard / Custom Available

- 4 Or 8 Lubrication Points

- <60 dB

- 400mm x 250mm x 260mm

- Automatic

- Industrial

- Fine Mesh Type

- Steel Body with ABS Cover

- 220V AC

- 50W

- EPC-4P / EPC-8P

- Easy Plug & Play

- PLC / Manual Switch Compatible

- Electric Gear Pump

- Microprocessor Based Controller

- 4mm / 6mm

- IP54

- LED Indicator for Status & Error

- 3 Liters

- Overload & Dry Run Protection

- Wall / Panel Mount

- 0.05-0.2 ml (per point, adjustable)

- 2-7 bar adjustable

- 5°C to 55°C

EPC 4 Or 8 Point Spray Lubrication System Trade Information

- Cash Advance (CA)

- 10 Unit Per Month

- 14 Days

- All India

Product Description

EPC 4 Or 8 Point Spray Lubrication System is a ruggedized and functional system. This lubrication system is equipped with high-precision components and units, which make it a functional lubrication system. It is used in industries including mechanical, automation, and others. The offered lubrication system does not degrade in quality or become inferior in the long run. Owing to its ruggedness and performance, we are seeing a huge demand for the EPC 4 Or 8 Point Spray Lubrication System in the marketplace.

Condition | New |

Brand | Dietronic - Italy |

Die Tronic SRL has suippled complete system of Sector Spray Lubrication System (SAGOMA) with conveyor roller for easy entry & exit of the sheet.

Precision Lubrication for Industrial Applications

The EPC Spray Lubrication System ensures reliable and consistent lubrication for critical industrial machinery. It features adjustable spray parameters to match diverse requirements and achieves optimal coverage on multiple points for enhanced machine longevity. Its robust microprocessor controller and electric gear pump enable user-friendly operation and precise control, supporting both manual and automated integration through PLC compatibility.

Plug & Play Installation and User-Friendly Operation

Installing the EPC spray lubrication system is straightforward, thanks to the plug & play design, compact dimensions, and flexible mounting options. With intuitive LED indicators and simple controls, operators can quickly adjust spray pressure and volume while monitoring system status and errors. The systems fine mesh filter maintains lubricant quality, and overload plus dry run protections provide added safety.

FAQs of EPC 4 Or 8 Point Spray Lubrication System:

Q: How do I install the EPC 4 or 8 Point Spray Lubrication System?

A: The system supports easy plug & play installation and can be wall or panel mounted. Simply connect the pipes (4mm/6mm), plug in the power supply (220V AC), connect to your PLC or manual switch, and follow the user manual to start operation.Q: What is the process for adjusting spray pressure and volume?

A: Spray pressure can be set anywhere between 2 and 7 bar, while spray volume per cycle is adjustable from 0.05 to 0.2 ml per point. Use the microprocessor-based controller to calibrate these parameters according to your machinerys lubrication needs.Q: When should I refill or maintain the reservoir?

A: The 3-liter reservoir should be checked periodically depending on the usage frequency. Refill with compatible lubricant when the level is low, and inspect the fine mesh filter to ensure the system operates efficiently.Q: Where should this lubricating system be used?

A: It is suitable for industrial environments where machinery requires accurate lubrication. Common applications include CNC machines, textile machinery, and packaging equipment. The IP54 rating ensures safe operation in dusty or damp conditions.Q: What are the benefits of using a microprocessor-based controller in this system?

A: The advanced controller offers precise spray and cycle adjustments, compatibility with PLC for automation, and LED indicators for status monitoring and error alerts, improving ease of use, safety, and lubrication reliability.Q: How does overload and dry run protection work in the EPC lubrication system?

A: The system is equipped with safety mechanisms that automatically halt operation if overload or dry run conditions are detected, safeguarding the pump and maintaining optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free