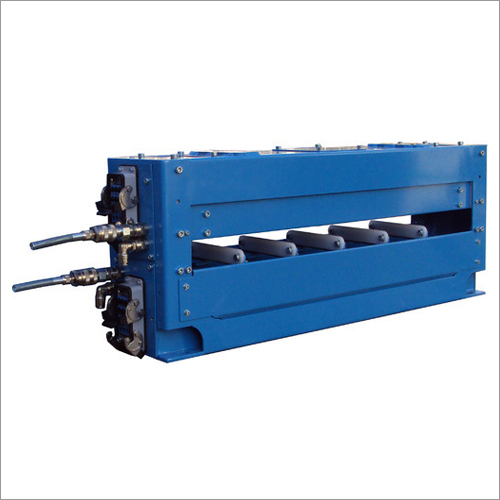

Press Room Electronic Spray Lubrication System

500000 INR

Product Details:

- Usage & Applications Press Room, Metal Forming Industries

- Model No Not Specified

- Automatic Grade Automatic

- Filter Type Fine Mesh

- Capacity Not Specified

- Size Standard

- Material Steel & High-grade Plastics

- Click to view more

X

Press Room Electronic Spray Lubrication System Price And Quantity

- 1 Unit

- 500000 INR

- Floor/Panel Mount

- 0.1 to 10 Seconds per Spray Cycle

- Electronic Proximity Sensors

- 12 Liters

- 2-6 Bar

- All Grades of Press Oils

- Adjustable Flow

- Microprocessor Based

- 8 (Adjustable)

- High-Pressure Polyurethane

- Emergency Stop, Overload Protection

- PLC Compatible

- 5°C to 50°C

- Low

- Uniform Mist

- Digital Touch Panel

Press Room Electronic Spray Lubrication System Product Specifications

- Not Specified

- Not Specified

- Steel & High-grade Plastics

- Fine Mesh

- Not Specified

- Standard

- Press Room, Metal Forming Industries

- Automatic

- Not Specified

- Not Specified

- Not Specified

- Industrial

- Low

- Floor/Panel Mount

- 0.1 to 10 Seconds per Spray Cycle

- Electronic Proximity Sensors

- 12 Liters

- 2-6 Bar

- All Grades of Press Oils

- Adjustable Flow

- Microprocessor Based

- 8 (Adjustable)

- High-Pressure Polyurethane

- Emergency Stop, Overload Protection

- PLC Compatible

- 5°C to 50°C

- Low

- Uniform Mist

- Digital Touch Panel

Press Room Electronic Spray Lubrication System Trade Information

- Cash Advance (CA)

- 10 Unit Per Month

- 14 Days

- All India

Product Description

Electronic Spray Lubrication System is unmatched in terms of design and functional efficiency. This lubrication system is extremely functional and long-lasting. It consists of high-precision components and units, which are responsible for its longevity and reliability. Press Room Electronic Spray Lubrication System does not degrade in quality or become inferior in the long run. Our customers can approach us to get the Electronic Spray Lubrication System at a sensible price.

Efficient Lubrication Control

Benefit from precise and uniform lubrication with adjustable flow settings and a digitally controlled spray pattern. This system supports eight nozzles, easily tailored to varying press room requirements. The microprocessor ensures consistent operation and optimal usage of press oil, reducing waste and maintenance efforts while enhancing machine longevity.

Safety and Convenience Redefined

Engineered with industrial safety standards in mind, this solution includes emergency stop, overload protection, and electronic proximity sensors. The CE-marked system is built for both floor and panel mounting, making it versatile for new installations or retrofits. An intuitive touch panel simplifies operation even in rigorous environments.

FAQs of Press Room Electronic Spray Lubrication System:

Q: How is the spray flow and pressure adjusted in this lubrication system?

A: The system allows users to easily modify both flow rate and spray pressure using the digital touch panel interface. Pressure can be set between 2 and 6 bar, while flow can be fine-tuned to match specific lubrication needs for different applications.Q: What types of lubricants can be used with the spray system?

A: This product is compatible with all grades of press oils used in industrial metal forming applications. It is designed to handle various viscosities without compromising spray quality or nozzle integrity.Q: Where can the Electronic Spray Lubrication System be installed?

A: The system is suitable for floor or panel mounting, providing flexibility in integration within press rooms or metal forming production lines. Its compact, standard-sized design and rugged materials support use in demanding industrial settings.Q: When should the spray cycle timing be adjusted, and how is it done?

A: Spray timing can be set from 0.1 to 10 seconds per cycle based on lubrication needs, which may change with different metal forming operations. Adjustments are managed via the digital touch panel, enabling precise control over application intervals.Q: What processes or industries benefit most from this system?

A: This lubrication system is ideal for metal forming industries, especially in press room environments. Processes involving stamping, forming, and pressing metals benefit from the uniform mist and controlled application, reducing friction and wear on equipment.Q: How does this system enhance operational safety?

A: With integrated emergency stop, overload protection, and electronic proximity sensors, the system prioritizes user and equipment safety. It is also CE-marked, assuring compliance with international safety standards.Q: What are the maintenance requirements for the lubrication system?

A: The design prioritizes low maintenance. Features such as high-pressure polyurethane hoses, fine mesh filtration, and reliable sensors mean routine checks are minimal, and component longevity is enhanced in harsh industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free