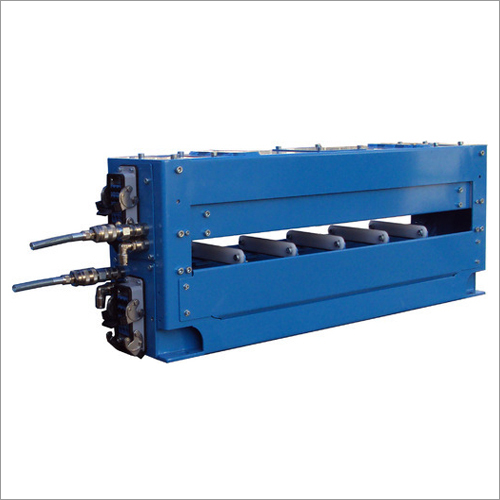

Electro-Pneumatic Lubrication System

200000 INR

Product Details:

- Capacity 2-5 Liters

- Size Standard

- Usage & Applications Industrial machinery lubrication; automated lubrication tasks

- Automatic Grade Semi-Automatic

- Model No EPLS-220

- Filter Type 10 micron mesh filter

- Grade Industrial Grade

- Click to view more

X

Electro-Pneumatic Lubrication System Price And Quantity

- 200000 INR

- 1 Unit

- IP54

- Panel & Wall Mountable

- Manually Adjustable

- LED Indication for Operation and Faults

- 4-6 bar

- 6 mm (OD)

- 4

- 0°C to 50°C

- Programmable Electronic Timer

- 30-1000 cSt

- 180 ml/min

- Gear Pump

- >50,000 operation cycles

- Integrated

- Overload and Dry Run Protection

Electro-Pneumatic Lubrication System Product Specifications

- 220V AC

- 7.2 kg (approximate)

- Industrial Grade

- 10 micron mesh filter

- EPLS-220

- 320mm x 220mm x 350mm (approximate)

- Semi-Automatic

- < 70 dB

- 2-5 Liters

- 18-25 W

- Standard

- Industrial machinery lubrication; automated lubrication tasks

- IP54

- Panel & Wall Mountable

- Manually Adjustable

- LED Indication for Operation and Faults

- 4-6 bar

- 6 mm (OD)

- 4

- 0°C to 50°C

- Programmable Electronic Timer

- 30-1000 cSt

- 180 ml/min

- Gear Pump

- >50,000 operation cycles

- Integrated

- Overload and Dry Run Protection

Electro-Pneumatic Lubrication System Trade Information

- Cash Advance (CA)

- 10 Unit Per Month

- 14 Days

- All India

Product Description

Backed by a team of diligent professionals, we are engrossed in supplying the top of the line Electro-Pneumatic Lubrication System that is widely acclaimed among our customers owing to its superior design, resilience, and performance. The offered system is used to assist the smooth and healthy operation of rotating machinery parts. It is used in the automation industry. The offered system helps in lubricating machinery parts such as dies, chains, gears, bearings, and cables, among others. Electro-Pneumatic Lubrication System can be purchased from us at a cost-effective price.

Reliable and Efficient Industrial Lubrication

The EPLS-220 is built for precise and reliable lubrication in industrial settings, offering consistent performance through its programmable electronic timer and gear pump mechanism. With adjustable output and multiple outlets, it supports varied lubrication needs for diverse machinery, ensuring every operation receives the optimum amount of lubricant at the correct intervals. The integrated safety features, robust power system, and clear status indications contribute to streamlined maintenance and heightened overall reliability.

Advanced Control and Safety Features

Equipped with a programmable control system and LED indicators for both operational status and faults, the EPLS-220 enhances user experience by facilitating easy monitoring and diagnosis. Overload and dry run protections, combined with a low level sensor and 10-micron filter, safeguard your equipment and the lubrication process. With a service life exceeding 50,000 operation cycles and IP54 protection, this system minimizes downtime and maintenance concerns.

FAQs of Electro-Pneumatic Lubrication System:

Q: How does the programmable electronic timer in the EPLS-220 lubrication system function?

A: The programmable electronic timer allows users to set lubrication intervals according to machinery requirements. This ensures lubricants are dispensed automatically at optimal times, reducing manual intervention and improving overall maintenance efficiency.Q: What types of industrial machinery is this lubrication system suitable for?

A: The EPLS-220 is designed for various industrial equipment that requires precise, automatic lubrication, including automated production lines, machine tools, and multi-point machinery that benefit from centralized lubrication.Q: When should the lubrication systems flow rate be adjusted manually?

A: Manual flow rate adjustment should be made when changing to machinery with different lubrication requirements or when switching to a lubricant of a different viscosity, ensuring each component receives the right amount of lubricant.Q: Where can the EPLS-220 lubrication system be installed?

A: This system is panel and wall mountable, offering flexible installation options in factory environments or machine rooms, wherever industrial machinery requires automated lubrication.Q: What process does the system use to protect against dry run and overload situations?

A: Built-in safety features, including overload and dry run protection, automatically halt the pump and alert the user via LED indicators if abnormal conditions are detected. This prevents equipment damage and maintains operational safety.Q: What are the main benefits of using an electro-pneumatic lubrication system like this one?

A: The EPLS-220 enhances equipment lifespan, reduces maintenance downtime, improves lubrication accuracy, and decreases the risk of manual errors. Its automated functions optimize resource usage and increase machinery efficiency.Q: How do the LED indications assist in the operation of this lubrication system?

A: Integrated LED indicators display the current operational status and highlight fault conditions, ensuring that maintenance staff can quickly identify and resolve any issues, minimizing unplanned downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email