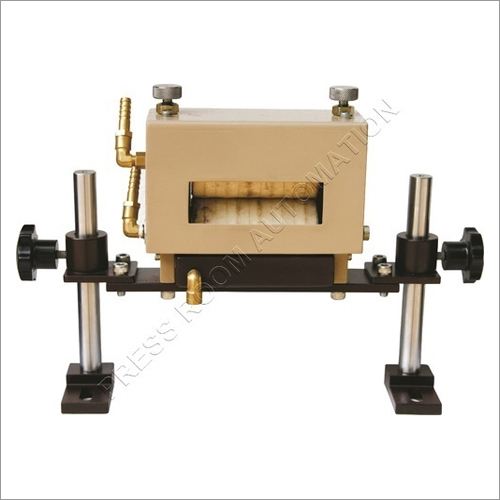

Coil Roller Lubrication System

350000 INR

Product Details:

- Automatic Grade Semi-Automatic

- Model No CRLS-7956

- Filter Type Fine mesh oil filter

- Usage & Applications Industrial coil rolling lubrication, metal stamping, sheet forming

- Capacity Up to 10 liters lubrication reservoir

- Size Standard industrial size (consult manufacturer)

- Material High-grade steel with powder-coated finish

- Click to view more

X

Coil Roller Lubrication System Price And Quantity

- 1 Unit

- 350000 INR

- 2-6 bar

- Hardened steel

- Overfill and low-output protection sensors

- Digital timer and flow control

- Suitable for synthetic, mineral, and water-based oils

- 2.5 meters

- 5°C to 55°C

- Manual and automatic settings

- Precision metering pump

- 300 mm

- 10 L

- Floor or coil line mountable

- Supports up to 40 m/min

Coil Roller Lubrication System Product Specifications

- 220V-240V, 50/60Hz

- Approx. 1200mm x 450mm x 650mm

- High-grade steel with powder-coated finish

- Standard industrial size (consult manufacturer)

- <70 dB

- Up to 10 liters lubrication reservoir

- Industrial coil rolling lubrication, metal stamping, sheet forming

- 56 kg

- Fine mesh oil filter

- 550W

- Industrial

- CRLS-7956

- Semi-Automatic

- 2-6 bar

- Hardened steel

- Overfill and low-output protection sensors

- Digital timer and flow control

- Suitable for synthetic, mineral, and water-based oils

- 2.5 meters

- 5°C to 55°C

- Manual and automatic settings

- Precision metering pump

- 300 mm

- 10 L

- Floor or coil line mountable

- Supports up to 40 m/min

Coil Roller Lubrication System Trade Information

- Cash Advance (CA)

- 10 Unit Per Month

- 14 Days

- All India

Product Description

We are offering the top-of-the-line Coils Lubricating System that is widely acclaimed among our customers owing to its superior design and unmatched functional efficiency. This lubricating system is used to assist the smooth and healthy operation of rotating machinery parts. It is used in industrial applications. Coils Lubricating System is designed to lubricate coil, strip, and Die irrespective of the type and thickness of the material. It is easy to use and maintain. Our customers can approach us to get the lubricating system at a reasonable price.

High-Precision Lubrication for Industrial Applications

The CRLS-7956 Coil Roller Lubrication System is designed to deliver exact lubrication for industrial operations like coil rolling and metal stamping. Its hardened steel rollers, fine mesh oil filtration, and digital controls ensure accurate and consistent lubricant distribution, minimizing waste and maximizing protection for working surfaces. The 10-liter reservoir and compatibility with various oil types make it adaptable to different manufacturing needs. Ideal for high-demand environments, it maintains reliability, efficiency, and product integrity.

User-Friendly Operation and Advanced Control

With a user-friendly digital timer and flow control, operators can easily switch between manual and automatic flow settings to match process requirements. The clearly marked control panel allows for precise adjustment, while safety sensors guard against overfilling and low lubricant output. This semi-automatic system streamlines maintenance and operation, contributing to smoother production workflows and reduced downtime.

FAQs of Coil Roller Lubrication System:

Q: How does the precision metering pump in the system ensure accurate lubrication?

A: The precision metering pump delivers controlled quantities of lubricant directly onto the roller, ensuring even distribution across the 300 mm width. This accuracy not only prevents over-lubrication or under-lubrication but also helps in reducing lubricant waste and improving product quality.Q: What types of lubricants are compatible with this lubrication system?

A: The system is designed to handle synthetic, mineral, and water-based oils, providing flexibility across a wide range of industrial applications. The fine mesh oil filter also ensures that particulates are removed regardless of lubricant type, maintaining system reliability.Q: When should the oil be refilled in the 10-liter tank?

A: The system includes overfill and low-output protection sensors that alert the operator when lubricant levels are low or when the tank is nearing capacity. It is important to monitor these indicators regularly and refill the tank when prompted, to avoid interruptions in operation.Q: Where can the Coil Roller Lubrication System be installed?

A: The unit is designed for versatility, supporting installation either on the floor or directly onto a coil line. This allows for adaptation to varied factory layouts and makes it suitable for different industrial environments.Q: What is the process for adjusting the lubricant flow rate?

A: Operators can choose between manual or automatic settings using the digital control panel. The flow rate can be fine-tuned according to the application speed, up to a maximum of 40 m/min, ensuring the right amount of lubrication is applied for the specific metal forming process.Q: How does the system enhance workplace safety and efficiency?

A: With integrated overfill and low-output sensors, as well as a maximum noise level below 70 dB, the system minimizes spills, downtime, and operator exposure to hazards. The semi-automatic operation reduces manual handling, improving both safety and productivity in industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free