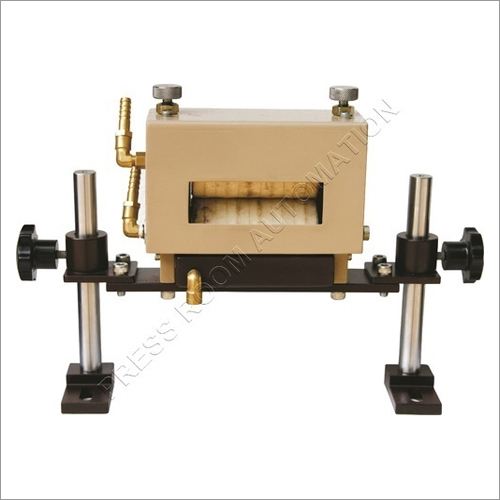

GLS -10 Gravity Roller Lubrication System

24000 INR

Product Details:

- Model No GLS-10

- Size Standard

- Filter Type Mesh Filter

- Material Mild Steel

- Capacity 10 Liters

- Automatic Grade Semi-Automatic

- Grade Industrial

- Click to view more

X

GLS -10 Gravity Roller Lubrication System Price And Quantity

- 24000 INR

- 1 Unit

- Low

- 5C 50C

- Floor/Frame Fixing Brackets

- Anti-Corrosive Coating

- Up to 100 mm Diameter

- Adjustable

- 5 Years (Average)

- Wide-Mouth with Safety Cap

- Precision Gravity Valve

GLS -10 Gravity Roller Lubrication System Product Specifications

- Manual (Gravity Operated)

- GLS-10

- 18 kg

- Industrial

- Semi-Automatic

- Standard

- 10 Liters

- Silent Operation

- Mesh Filter

- Mild Steel

- 500 mm x 250 mm x 350 mm

- Low

- 5C 50C

- Floor/Frame Fixing Brackets

- Anti-Corrosive Coating

- Up to 100 mm Diameter

- Adjustable

- 5 Years (Average)

- Wide-Mouth with Safety Cap

- Precision Gravity Valve

GLS -10 Gravity Roller Lubrication System Trade Information

- Cash Advance (CA)

- 10 Unit Per Month

- 14 Days

- All India

Product Description

GLS - 10 Gravity Roller Lubricating System is popularly known among our customers owing to its high build quality, reliable performance, and longevity. The offered lubricating system is extremely functional and efficient. It is equipped with precision components and parts that make lubricating easy. GLS - 10 Gravity Roller Lubricating System is easy to install and use. Our customers can approach us to get the lubricating system at a cost-effective price.

Versatile Roller Compatibility

The GLS-10 accommodates a wide variety of roller sizes up to 100 mm diameter, making it suitable for diverse industrial applications. Whether installed in manufacturing, packaging, or logistics facilities, its adaptable design ensures efficient lubrication for all compatible roller systems without frequent adjustments.

Efficient Lubrication Control

Precision gravity valves and adjustable lube outlets allow for accurate regulation of lubrication flow, helping prevent waste and optimize roller performance. The wide-mouth reservoir with a secure safety cap ensures convenient refilling, while the mesh filter maintains lubricant purity for uninterrupted operation.

Robust Construction & Easy Installation

Manufactured with mild steel and an anti-corrosive coating, the GLS-10 promises long-term durability and reliability. Installation is simplified with included floor or frame fixing brackets, making the system versatile for different industrial settings. Low maintenance and silent operation further enhance user convenience.

FAQs of GLS -10 Gravity Roller Lubrication System:

Q: How is the GLS-10 Gravity Roller Lubrication System installed?

A: The GLS-10 can be installed using floor or frame fixing brackets provided with the system, allowing secure attachment to different types of industrial setups. Its compact dimension supports easy integration without extensive modifications.Q: What types of rollers are compatible with the GLS-10 lubrication system?

A: This system is designed for rollers with diameters up to 100 mm, making it suitable for a broad range of industrial roller applications, including manufacturing lines and material handling conveyors.Q: When should the lubricant reservoir be refilled in the GLS-10 system?

A: Refilling is required when the lubricant level drops near the minimum mark inside the 10-liter reservoir. The wide-mouth filling port and safety cap facilitate quick and safe replenishment, minimizing downtime.Q: Where is the GLS-10 lubrication system commonly used?

A: The GLS-10 is typically applied in industrial environments such as factories, logistics centers, and packaging facilities where consistent and efficient roller lubrication is essential for operational reliability.Q: How does the precision gravity valve benefit the lubrication process?

A: The precision gravity valve enables fine-tuned control of lubricant flow to the rollers, preventing over-lubrication and ensuring uniform distribution. This helps maximize roller lifespan and reduces lubricant waste.Q: What maintenance is required for the GLS-10 Gravity Roller Lubrication System?

A: The system requires minimal maintenance, mainly periodic cleaning of the mesh filter and inspection of outlets for blockages. Regular checks of lubricant levels and valve function help sustain peak performance throughout its average five-year service life.Q: What are the main advantages of using the GLS-10 lubrication system?

A: Key advantages include its durability due to anti-corrosive materials, adjustable lubrication flow, compatibility with large rollers, low noise operation, and easy refilling and maintenance. These features contribute to extended roller life and reduced operational costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email