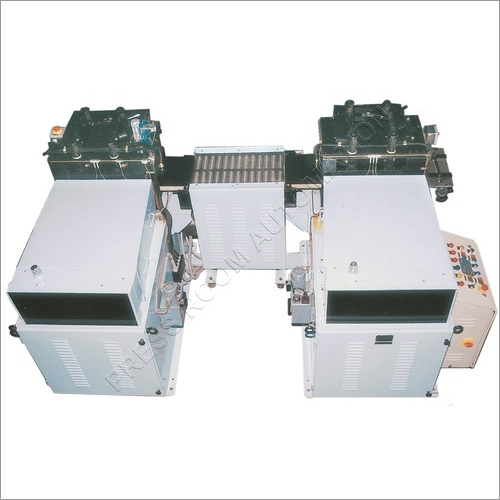

Single Component Leveller

1500000 INR

Product Details:

- Size Standard

- Features Single Component Operation, Adjustable Roller Gap, Heavy-Duty Structure

- Surface Finish Smooth

- Shape Rectangular Frame

- Capacity Up to 10 mm Thickness

- Motor Power 2 HP

- Drive Type Gear Motor Driven

- Click to view more

X

Single Component Leveller Price And Quantity

- 1 Unit

- 1500000 INR

- Digital Touch Control

- 1000 mm

- Floor-Mounted

- Digital PLC Control

- IP54

- Left to Right

- 0°C to 50°C

- 4 meters

- Low

- 100 mm

- 12 m/min

- Wooden Crate

- Hardened Alloy Steel

Single Component Leveller Product Specifications

- Single Component Operation, Adjustable Roller Gap, Heavy-Duty Structure

- Industrial Grey

- Standard

- Iron

- Rectangular Frame

- Automatic Central Lubrication

- 2.2 kW

- Smooth

- Sheet Metal Leveling, Industrial Automation, Roll Forming Line

- <75 dB

- Electric

- Advanced Automated Technology

- 220-420 Volt (v)

- Up to 10 mm Thickness

- 6-8 Bar

- Galvanized

- 2 HP

- 1250 mm x 650 mm x 1100 mm

- 420 kg

- Gear Motor Driven

- Roller Diameter 68 mm

- Machine Parts

- Digital Touch Control

- 1000 mm

- Floor-Mounted

- Digital PLC Control

- IP54

- Left to Right

- 0°C to 50°C

- 4 meters

- Low

- 100 mm

- 12 m/min

- Wooden Crate

- Hardened Alloy Steel

Single Component Leveller Trade Information

- Cash Advance (CA)

- 10 Unit Per Month

- 14 Days

- All India

Product Description

We are actively engrossed in supplying the top of the line Single Component Leveller that is widely acclaimed among our customers owing to its superior design and unmatched functional efficiency. This component leveller is used in the automation industry. The leveller is designed and developed in our state-of-the-art production division making the best use of pioneering in-house tools and techniques. Owing to its high operational efficiency, reliability, and ruggedness, this component leveller is high in demand in the marketplace. Our customers can approach us to get the product at a reasonable price.

Precision Performance and Robust Build

Designed for demanding industrial environments, the Single Component Leveller delivers consistent and accurate sheet metal leveling. The machine combines advanced automated technology with a heavy-duty structure, supporting operational reliability and longevity. The use of hardened alloy steel rollers and a galvanized surface finish ensures resistance to wear and corrosion, making it suitable for continuous use.

User-Friendly Digital Control and Low Maintenance

Featuring a digital PLC control system and an intuitive digital touch panel, operators can effortlessly manage functions and monitor machine status in real-time. Thanks to its automatic central lubrication and streamlined component interaction, the leveller requires minimal intervention, reducing downtime and ensuring a low-maintenance experience.

Versatile Applications and Safety Features

This leveller is tailored for sheet metal leveling, industrial automation, and roll forming lines in manufacturing settings. The floor-mounted, rectangular frame and IP54-rated enclosure provide excellent stability and protection. The machines adjustable roller gap and advanced gear motor drive allow adaptation to different sheet thicknesses and materials, maximizing flexibility and productivity.

FAQs of Single Component Leveller:

Q: How does the control system of the Single Component Leveller enhance operational efficiency?

A: The leveller utilizes a digital PLC control system with a digital touch panel display, which allows operators to easily adjust settings, monitor real-time performance, and manage operations efficiently. This streamlined interface enhances productivity and reduces operator workload.Q: What materials and sheet sizes can the leveller accommodate?

A: This machine is designed for iron sheets with a galvanized surface, handling sheet widths from 100 mm to 1000 mm and thicknesses up to 10 mm. It is ideal for diverse applications in industrial automation and roll forming lines.Q: Where should the Single Component Leveller be installed for optimal performance?

A: The leveller is floor-mounted and should be placed in a well-ventilated industrial space within the ambient temperature range of 0C to 50C. Installation on an even surface ensures structural stability and optimal operation.Q: When is maintenance required, and how is it performed?

A: Thanks to its automatic central lubrication system and robust construction, the leveller requires minimal maintenance. Regular checks on lubrication, power connections, and the control panel are advisable, but daily interventions are rarely necessary.Q: What is the typical process for sheet metal leveling with this unit?

A: Sheet metal is fed from the left, passing through adjustable, hardened steel rollers driven by a gear motor. The rollers flatten and level the sheet, which then exits on the right. The operator can fine-tune roller gaps and control parameters for different material thicknesses via the digital touch panel.Q: What are the main benefits of using this leveller in industrial settings?

A: Key benefits include high operational speed (up to 12 m/min), low noise level (<75 dB), advanced automation for consistent results, reduced maintenance demands, and adaptability to various sheet sizes. The robust, IP54-protected structure ensures safety and extended service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free