Slitting Line For Mild And Galvanized Steel

10000000 INR

Product Details:

- Noise Level 85 dB

- Voltage 380-440 V

- Machine Type High-Speed Slitting Line

- Connectivity Options HMI/PLC Remote Access

- Frequency 50/60 Hz

- Drive AC Frequency Drive

- Operating Temperature 0-45C

- Click to view more

X

Slitting Line For Mild And Galvanized Steel Price And Quantity

- 10000000 INR

- 1 Unit

- Provided

- 30 mm

- 180 mm

- Up to 30 (Depending on width and thickness)

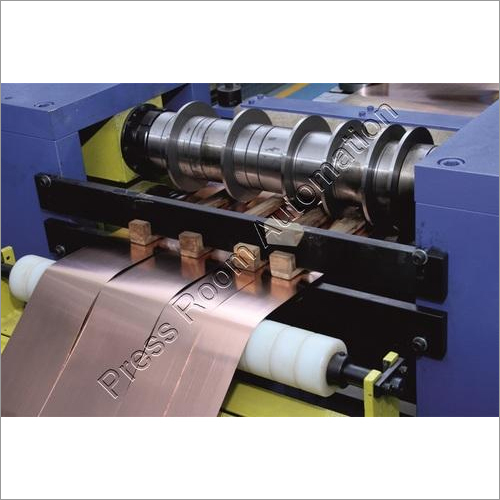

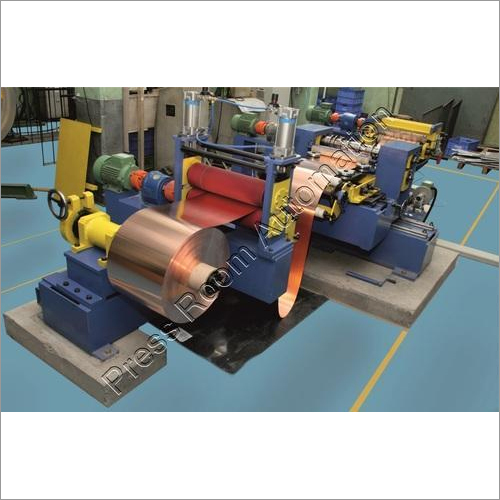

- Uncoiler, Pinch Roll, Leveler, Slitter, Recoiler, and Exit Coil Car

- High-Efficiency Drive Motors

- English/Local Language Support

- Pneumatic/Hydraulic

- 20-60 meters/minute

- Mild Steel, Galvanized Steel

- 10 inch Color Touchscreen

- 30 Tons

- Alloy Tool Steel

- Overload and Short Circuit Protection

- 0.3 mm - 6.0 mm

- High-Chrome Alloy Steel

- 200-350 mm

- 500 mm - 2000 mm

Slitting Line For Mild And Galvanized Steel Product Specifications

- Adjustable

- Slitting Line for Mild & Galvanized Steel

- Precision Slitting Technology

- 25000 mm x 5000 mm x 2500 mm

- 50/60 Hz

- 85 dB

- 75 kW

- Electric

- 380-440 V

- High-Speed Slitting Line

- HMI/PLC Remote Access

- 3,500 Tons/month

- Yes

- Water-Cooled

- 75 kW

- SLS-MGS-2500

- 38000 kg

- Welded Steel Structure

- Automatic Centralized Lubrication

- 0-45C

- Automatic

- AC Frequency Drive

- Suitable for slitting coils of mild and galvanized steel in steel processing plants

- Yellow

- 0.1 mm

- Galvanized

- 75 kW

- PLC Based Automatic Control

- Provided

- 30 mm

- 180 mm

- Up to 30 (Depending on width and thickness)

- Uncoiler, Pinch Roll, Leveler, Slitter, Recoiler, and Exit Coil Car

- High-Efficiency Drive Motors

- English/Local Language Support

- Pneumatic/Hydraulic

- 20-60 meters/minute

- Mild Steel, Galvanized Steel

- 10 inch Color Touchscreen

- 30 Tons

- Alloy Tool Steel

- Overload and Short Circuit Protection

- 0.3 mm - 6.0 mm

- High-Chrome Alloy Steel

- 200-350 mm

- 500 mm - 2000 mm

Slitting Line For Mild And Galvanized Steel Trade Information

- Cash Advance (CA)

- 10 Unit Per Month

- 14 Days

- All India

Product Description

Brand | Faspar |

FASPAR Spa manufacture high quality lines for Mild and Galvanized Steel.

Types of Material:

- Cold rolled, hot rolled, pickled, surface treated.

- Material Surfaces

- Dry or oiled.

Specifications:

- Width from 300 to 2200 mm

- Coils capacity from 5 to 40 tons

- Speed up to 300 m/min

- Thickness up to 20 mm

Engineered for High Efficiency and Precision

This slitting line integrates cutting-edge precision slitting technology and a PLC-based control system for accurate cutting within 0.1 mm. The robust welded steel structure and energy-efficient drive motors ensure reliability during continuous operation. Operators enjoy a user-friendly experience with a 10-inch color HMI touchscreen and multilingual support for seamless control.

Comprehensive Safety and User Protections

To prioritize operator safety and equipment longevity, the line includes both overload and short-circuit electrical protections. Safety interlocks are built in, ensuring that all maintenance and operational activities are carried out securely. Additionally, a low-noise design and adjustable pressure controls foster a comfortable and safe workspace environment.

Streamlined Performance for Versatile Applications

Capable of handling coils up to 30 tons and producing up to 30 strips depending on width and thickness, this machine addresses a wide range of slitting needs in steel processing plants. Its water-cooled and automatically lubricated systems support consistent operation, making it ideal for intensive industrial applications and high production demands.

FAQs of Slitting Line For Mild And Galvanized Steel:

Q: How does the slitting process work on this machine?

A: The slitting line unwinds steel coils from the uncoiler, levels the material, and passes it through a high-precision slitter equipped with alloy tool steel knives to cut the coil into strips. The recoiler then rewinds the slit strips, and the exit coil car facilitates handling the finished product. All steps are automatically managed using a PLC-based control system.Q: What materials can be processed with this slitting line?

A: This slitting line is designed for processing both mild steel and galvanized steel coils, making it suitable for diverse steel processing requirements in industrial environments.Q: Where is this slitting line typically used?

A: The machine is primarily utilized in steel processing plants and manufacturing facilities that require efficient and precise slitting of mild and galvanized steel coils for further fabrication or distribution.Q: What are the key specifications regarding coil dimensions and strip output?

A: The machine handles coil widths between 500 mm and 2000 mm, thicknesses from 0.3 mm to 6.0 mm, and weights up to 30 tons. It can produce strips with a minimum slit width of 30 mm and up to 30 strips per coil, depending on the materials width and thickness.Q: What benefits does the HMI touchscreen and remote connectivity offer?

A: The 10-inch color touchscreen HMI enables intuitive, real-time monitoring and adjustment of operations. Remote HMI/PLC connectivity allows for off-site diagnostics, troubleshooting, and performance tracking, enhancing operational efficiency.Q: How does the line ensure operational safety and equipment protection?

A: The line is equipped with overload and short-circuit protection, safety interlocks, and centralized lubrication to prevent accidents and maintain machine integrity, ensuring both operator safety and machine longevity.Q: When should maintenance be performed on the slitting line?

A: Routine checks on the water-cooling system, lubrication unit, and cutting knives should be scheduled according to operating hours and workload. The automatic centralized lubrication system and integrated safety features help extend maintenance intervals, but periodic inspections are essential for optimal performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free