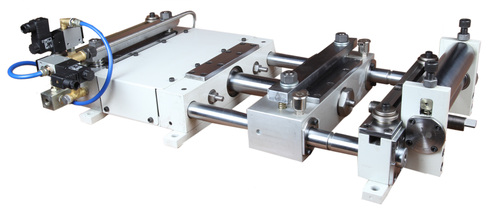

Pneumatic Thin Strip Feeder with Pilot Release

Product Details:

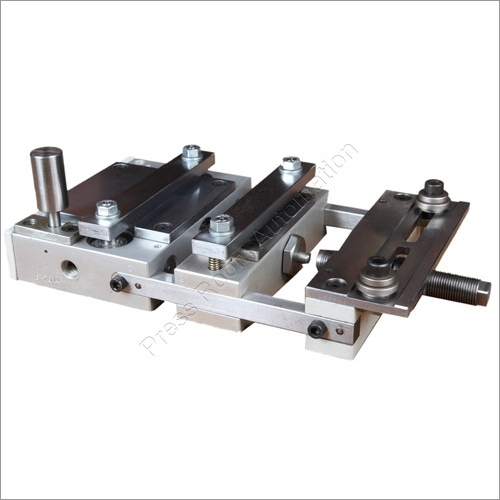

- Structure Compact dual-guide rails

- Media Compressed air

- Material High-grade steel

- Air Consumption 10 SCFM

- Click to view more

X

Pneumatic Thin Strip Feeder with Pilot Release Price And Quantity

- 1 Unit

Pneumatic Thin Strip Feeder with Pilot Release Product Specifications

- Compact dual-guide rails

- Compressed air

- High-grade steel

- 10 SCFM

Pneumatic Thin Strip Feeder with Pilot Release Trade Information

- 5-10 Days

Product Description

The Feeder will be actuated by Remote Valve via Solenoid Valve, Proximity Sensor and Cam Assembly along with pilot release mechanism for piloted tools and thin strip guiding device for feeding material below 0.5 mm thickness.Integrated Pilot Release Mechanism

Experience enhanced accuracy during material feeding with the inbuilt pilot release, allowing precise synchronization with metal stamping processes. The integration supports consistent quality and improved cycle rates in automated production environments.

High Feeding Accuracy & Strip Compatibility

Engineered for thin metal strips up to 1.5 mm, the feeder delivers an exceptional 0.1 mm feeding accuracy. Consistent performance ensures high-fidelity stamped components, minimizing material waste and maximizing throughput for automation lines.

Robust Construction & Safety Features

Manufactured using high-grade steel and featuring an anti-corrosive coating, the feeder delivers reliable performance in challenging industrial settings. Its quiet operation and automatic lubrication also support safer, cleaner, and more comfortable workspace conditions.

FAQs of Pneumatic Thin Strip Feeder with Pilot Release:

Q: How does the integrated pilot release mechanism improve feeding accuracy?

A: The pilot release mechanism synchronizes the pneumatic feeding action with the press, allowing precise positioning of thin strips during stamping. This integration significantly reduces misfeeds and ensures a feeding accuracy of 0.1 mm throughout operation.Q: What types of metal strips can the feeder handle effectively?

A: The feeder is suitable for thin metal strips with thicknesses up to 1.5 mm. It functions exceptionally well with various metals used in stamping and automated production environments, maintaining consistent feed regardless of material type.Q: When should I perform maintenance on the feeders lubricator?

A: Thanks to its inbuilt automatic lubricator, regular manual lubrication is not necessary. However, periodic inspections are recommended every three to six months to ensure optimal function and detect any potential blockages or wear.Q: Where can the feeder be mounted in stamping or automation setups?

A: The universal mounting holes allow flexible installation on a wide range of press machines or automation lines. This ensures compatibility with existing setups and simplifies integration during expansion or upgrades.Q: What is the process for adjusting operating pressure and air consumption?

A: The feeder operates efficiently within a pressure range of 57 bar and consumes approximately 10 SCFM of compressed air. Adjustments can be made via the supply regulator to match application requirements, ensuring optimal feeding speed and accuracy.Q: How does the anti-corrosive coating benefit long-term use?

A: The anti-corrosive coating safeguards the high-grade steel body against rust and degradation, extending the feeders lifespan and reliability, especially in moisture-prone or aggressive manufacturing atmospheres.Q: What are the practical usage benefits in an automation line?

A: Operators benefit from precise, consistent strip feeding, reduced downtime, and low noise levels. The feeder improves process repeatability, minimizes maintenance, and supports rapid changeovers for different strip thicknesses in automated metal stamping workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free