WE ARE TEAM PRESS ROOM AUTOMATION !

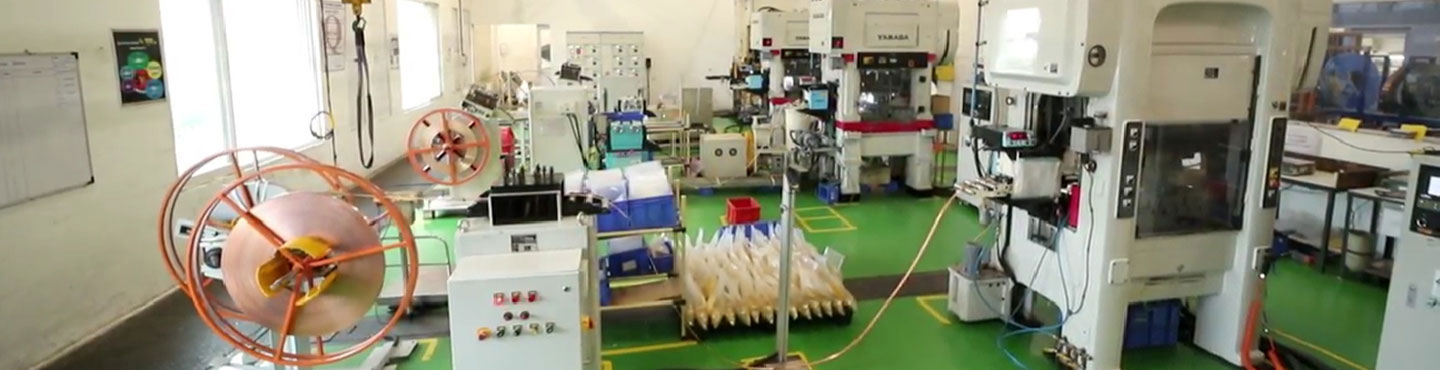

Our purpose is to create simple automation system in coil processing industry with proper design, excellent manufacturing, stringent quality control, and skilled installation. With more than 30 years of experience in the field of press automation, Press Room Automation is today able to satisfy many productivity needs and offer a production solution to meet the customers specific requirement. We bring in the best expertise and the most spread out industry network.

We are 100% focused on designing and constructing of a series of automated machines for sheet metal working and are proud to have installed more than 6000 equipments all over the world.We provide best Application Engineering & Prompt after Sales service throughout the country.

Over the last 5 years, the Company had already tied-up with International giants for offering on complete technological solution in future automating the sheet metal component manufacturing.Thanks to our computerized technical office, Press Room is able to track the order from the planning phase to design, manufacturing, warehouse management and installation. Utilizing our 2D/3D CAD system not only are these functions performed but also inventory control. Press Room utilizes CNC and FMS machine tools with latest technology capable to of producing component with tight tolerance.

Our purpose is to create simple automation system in coil processing industry with proper design, excellent manufacturing, stringent quality control, and skilled installation. With more than 30 years of experience in the field of press automation, Press Room Automation is today able to satisfy many productivity needs and offer a production solution to meet the customers specific requirement. We bring in the best expertise and the most spread out industry network.

We are 100% focused on designing and constructing of a series of automated machines for sheet metal working and are proud to have installed more than 6000 equipments all over the world.We provide best Application Engineering & Prompt after Sales service throughout the country.

Over the last 5 years, the Company had already tied-up with International giants for offering on complete technological solution in future automating the sheet metal component manufacturing.Thanks to our computerized technical office, Press Room is able to track the order from the planning phase to design, manufacturing, warehouse management and installation. Utilizing our 2D/3D CAD system not only are these functions performed but also inventory control. Press Room utilizes CNC and FMS machine tools with latest technology capable to of producing component with tight tolerance.

Our Inventions

Our company was the first to introduce following equipment and machinery in the Indian market:

- Indian Pneumatic Feeder

- NC Servo Roll Feeder

- Concept of complete automated lines in small scale & medium scale industry

- Precision Component Leveller with full automation for loading & unloading

- Heavy Duty Press Feed lines for 6mm to 10mm thickness coils for Automobile segment

- Automated & cost-effective Cut to Length Lines for thin / delicate full width coils

- Multi-Station Flexible Punching Press with programmable feed length & programmable punching sequence.

Team & Infrastructure

We have recruited a team of experienced and diligent employees who have helped us in setting up a modern infrastructural facility in Maharashtra. The facility is divided into several smaller units like manufacturing, R&D, quality, warehousing, packaging, administration, sales & marketing, etc., which are managed by the respective team members. All our employees work together to attain the predefined goals of our company like manufacturing Coils Lubricating System, Light Series Pneumatic Feeder, etc., of unmatched quality at competitive prices. With the assistance of our resources, both human and infrastructure, we are running our business activities effortlessly.

Applications

The performance efficiency of our Coils Lubricating System and other equipment is one of the main features for which these equipment are highly demanded for manufacturing a large variety of products like Sheet Metal Components, Electronic Parts, Gasket Manufacturing, Racking System, Electrical Stamping, Luminaries, Electric Motor Stamping, etc.

Reason to Choose Us: Client Contentment

The major reason for which our clients prefer allying with us is our unwavering commitment to achieve complete client contentment. From honesty to quality and integrity to accountability, we focus on all these business principles to earn the trust of our clients and help them in the best possible way. We also follow customer-centric approaches to understand their needs well. Besides, we entertain their feedback and suggestions to provide them with the best range of Coils Lubricating System, Light Series Pneumatic Feeder and other equipment.

Development

We entertain market feedback to improve the existing products and focus on new machine design and equipment. Our company spends 5% of our overall turnover on our R&D.

Future

We aim to grow with changing time by collaborating with the other reputed International companies and improve our equipment gamut.