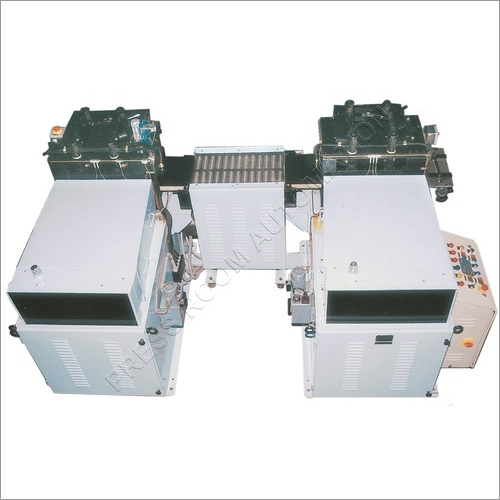

Automatic PLC Controlled Part Leveller

2000000 आईएनआर

उत्पाद विवरण:

- क्षमता Up to 4000 mm/min (feed rate)

- लुब्रिकेटिंग सिस्टम Centralized Automatic Lubrication

- शोर का स्तर ≤ 65 dB

- उपयोग/अनुप्रयोग Sheet Metal Leveling, Part Levelling in Manufacturing Lines

- सतह की फ़िनिश Smooth/Polished

- ड्राइव टाइप Chain/Synchronized Motor Drive

- व्यास Roller Dia 56 mm (Typical)

- Click to view more

X

स्वचालित पीएलसी नियंत्रित पार्ट लेवलर मूल्य और मात्रा

- यूनिट/यूनिट

- 1

- Up to 850 mm

- High Strength Alloy Steel

- Wooden Crate

- Siemens/Mitsubishi PLC

- Fully Automatic

- Emergency Stop, Overload Protection, Door Interlock

- 11 (Top 5, Bottom 6)

- Manual & Auto Fine Tuning

- Floor Mounted

- 8 kWh (max)

- 0.3 mm - 3.2 mm

- HMI Touch Screen

- 0°C to 45°C

- Digital IO & नेटवर्क Ready

- Adjustable via PLC

स्वचालित पीएलसी नियंत्रित पार्ट लेवलर उत्पाद की विशेषताएं

- 4 kW

- लोहा

- ≤ 65 dB

- Standard/Custom

- Sheet Metal Leveling, Part Levelling in Manufacturing Lines

- Rectangular Body

- सफ़ेद

- मशीन के पुर्जे

- 1800 kg

- 2300 mm x 1100 mm x 1350 mm

- 220-420 वोल्ट (v)

- 5 kW

- Chain/Synchronized Motor Drive

- Centralized Automatic Lubrication

- गैल्वेनाइज्ड

- Roller Dia 56 mm (Typical)

- 0.5-0.8 MPa

- Up to 4000 mm/min (feed rate)

- Smooth/Polished

- Up to 850 mm

- High Strength Alloy Steel

- Wooden Crate

- Siemens/Mitsubishi PLC

- Fully Automatic

- Emergency Stop, Overload Protection, Door Interlock

- 11 (Top 5, Bottom 6)

- Manual & Auto Fine Tuning

- Floor Mounted

- 8 kWh (max)

- 0.3 mm - 3.2 mm

- HMI Touch Screen

- 0°C to 45°C

- Digital IO & नेटवर्क Ready

- Adjustable via PLC

स्वचालित पीएलसी नियंत्रित पार्ट लेवलर व्यापार सूचना

- कैश एडवांस (CA)

- 10 प्रति महीने

- 14 दिन

- ऑल इंडिया

उत्पाद विवरण

Experience opulent precision in sheet metal manufacturing with our Automatic PLC Controlled Part Leveller. Engineered with Siemens/Mitsubishi pivotal controls and HMI touch screen display, this machine delivers reliable automation at a special promotional rate. Its 11 high-strength alloy rollers provide lofty leveling accuracy for input widths up to 850 mm and thicknesses from 0.3 to 3.2 mm. Fully network ready, it ensures seamless integration and exceptional value, with advanced safety features and lowest power consumption. This is your chance to own a truly automated levelling solution at the lowest price in India.

Advanced Features for Diverse Applications

The Automatic PLC Controlled Part Leveller features 11 durable alloy rollers, centralized automatic lubrication, and both manual and auto fine tuning. Capable of feed rates up to 4000 mm/min, it is ideal for part levelling and sheet metal processing in manufacturing lines, automotive plants, and fabrication workshops. The smooth-polished surface finish accommodates iron, stainless steel, and other alloys, delivering uniform results across broad application areas. Its floor-mounted, robust rectangular body ensures stable, efficient operations.

Sample Availability and Hassle-Free Order Processing

Obtain a sample of the Part Leveller with streamlined order processing. We serve the main domestic market across India, guaranteeing swift handover and secure transportation in wooden crates. Flexible payment terms are available to suit varying business needs, providing ease and assurance throughout your purchase cycle. Partner with us for timely delivery, expert support, and a simplified buying experiencecovering everything from enquiry to commissioning on your shop floor.

Advanced Features for Diverse Applications

The Automatic PLC Controlled Part Leveller features 11 durable alloy rollers, centralized automatic lubrication, and both manual and auto fine tuning. Capable of feed rates up to 4000 mm/min, it is ideal for part levelling and sheet metal processing in manufacturing lines, automotive plants, and fabrication workshops. The smooth-polished surface finish accommodates iron, stainless steel, and other alloys, delivering uniform results across broad application areas. Its floor-mounted, robust rectangular body ensures stable, efficient operations.

Sample Availability and Hassle-Free Order Processing

Obtain a sample of the Part Leveller with streamlined order processing. We serve the main domestic market across India, guaranteeing swift handover and secure transportation in wooden crates. Flexible payment terms are available to suit varying business needs, providing ease and assurance throughout your purchase cycle. Partner with us for timely delivery, expert support, and a simplified buying experiencecovering everything from enquiry to commissioning on your shop floor.

FAQs of Automatic PLC Controlled Part Leveller:

Q: How does the PLC control system enhance operational efficiency?

A: The Siemens/Mitsubishi PLC system automates the levelling process, allowing real-time adjustment and monitoring. This minimizes human error, ensures consistent output quality, and boosts overall workflow efficiency.Q: What is the recommended usage scenario for this part leveller?

A: It is designed for part levelling in sheet metal fabrication, manufacturing lines, and automotive sectors, handling materials up to 850 mm wide and thicknesses from 0.3 to 3.2 mm.Q: When can I expect delivery after placing an order?

A: Once order processing and payment terms are confirmed, our team coordinates prompt handover and transportation, typically within standard industry lead times for domestic shipments.Q: Where are the main markets supported by your company?

A: We primarily support the Indian domestic market with reliable delivery and technical service, ensuring access to our automated part levelling solutions nationwide.Q: What safety features does the Part Leveller include?

A: Safety options include emergency stop buttons, overload protection, and door interlocks, providing a secure operational environment for all users.Q: How is installation managed at customer sites?

A: The machine is floor mounted for stability and delivered in secure wooden crates. Our team offers guidance and support for seamless installation and commissioning.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें